When talking about Crosslink foam, two aspects are fundamental in defining its characteristics and the use to which the material will be put: hardness and density. But what are the differences between each and what do they define in terms of usefulness?

Crosslink Foam Hardness

In simple terms, the hardness of a material refers to how flexible or stiff it is.

How is hardness measured?

A laboratory instrument called durometer is used to measure the hardness of a material. Different types of hardness testers are used for different materials:

- Shore A: for soft rubbers, waxes, and leather items.

- Shore B: medium scale.

- Shore C: for rubber, medium hard plastics, and plaster.

- Shore D: for rubber and hard plastics.

- Shore DO: for high density textile rolls.

- Shore O: for medium density rolls.

- Shore OO: for foam rubber, sponges, and low-density textile rolls.

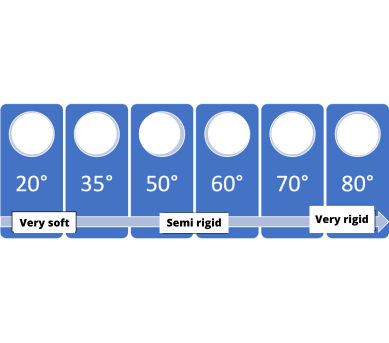

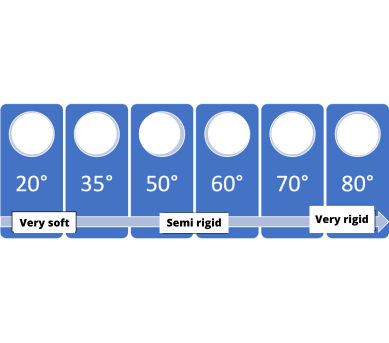

As for Crosslink polyethylene- or EVA-based foam, the measurement is expressed in Shore C degrees and the higher the number, the higher the hardness. The hardness degrees most commonly used in the industry are 20°, 35°, 50°, 60°, 70° and 80°. The following table shows the flexibility or stiffness of a Crosslink foam material in Shore C degrees:

Crosslink Foam Density

The density of any material equals its mass (weight) over a given volume. It is not always proportional to the firmness of the material, which depends on the formula used in its manufacturing, although generally different types of Crosslink foam with higher weight are firmer.

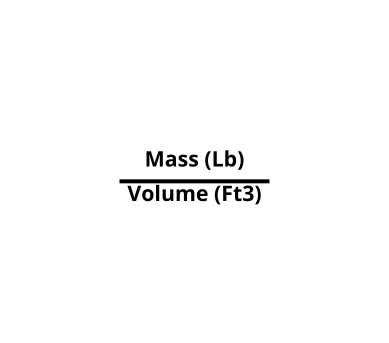

Density can be measured by means of a simple equation, shown below:

Mass is weighed on a scale, the sample is usually being cut 10 mm thick by 10 cm in length and width (volume).

The most common Crosslink densities for commercial use are 2lb/ft3, 4lb/ft3, 6lb/ft3, 8lb/ft3.

In conclusion, hardness is the rigidity of the material (how flexible or stiff it is), and density is how heavy the material is.

At Evacolors we have developed and commercialized Crosslink Foam in different presentations for over 20 years. We have own formulas to meet the needs of different industries. Contact us for customized advise.