When you finish reading this article, you will have different tips to help you maximize the use of the final Crosslink foam piece you receive as a raw material for your business.

Regardless of the industry you are in, getting the most out of the material you use will help reduce costs and improve profits. As Crosslink foam manufacturers and experts in its properties, we offer you some valuable advice to optimize the performance of your product.

1. Crosslink foam expands equally:

Thanks to its cellular structure and crosslinking properties, Crosslink foam expands evenly in both length and width, allowing you to cut it in any direction. Consider the following key aspects:

- Design effective cutting patterns: To maximize the use of Crosslink foam sheets or rolls, calculate and determine the most efficient cutting pattern. Analyze the required measurements and shapes, and utilize design software or calculation tools to ensure the best arrangement of pieces.

- Calculate material quantity: Determine the exact amount of Crosslink foam you need, considering the size of the pieces and products you plan to manufacture, as well as expected cutting margins and waste.

- Define yield per sheet or roll: Calculate how many pieces you can obtain from each unit of Crosslink foam purchased to determine the yield per sheet or roll.

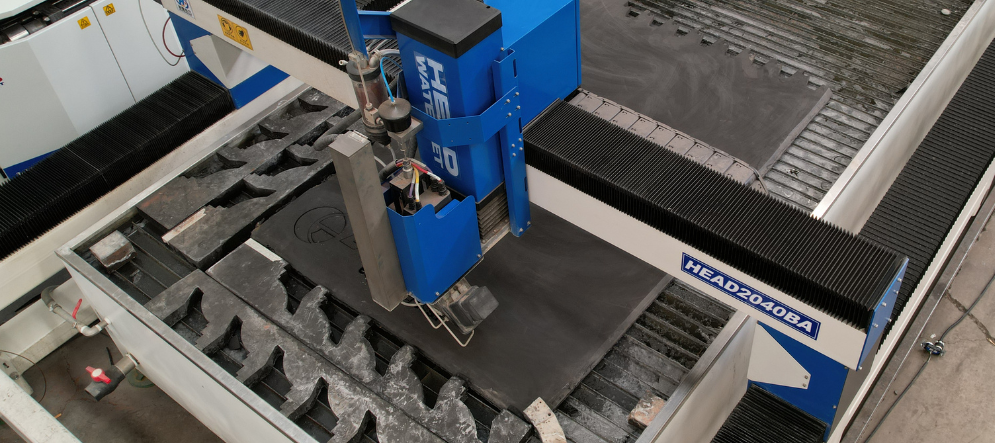

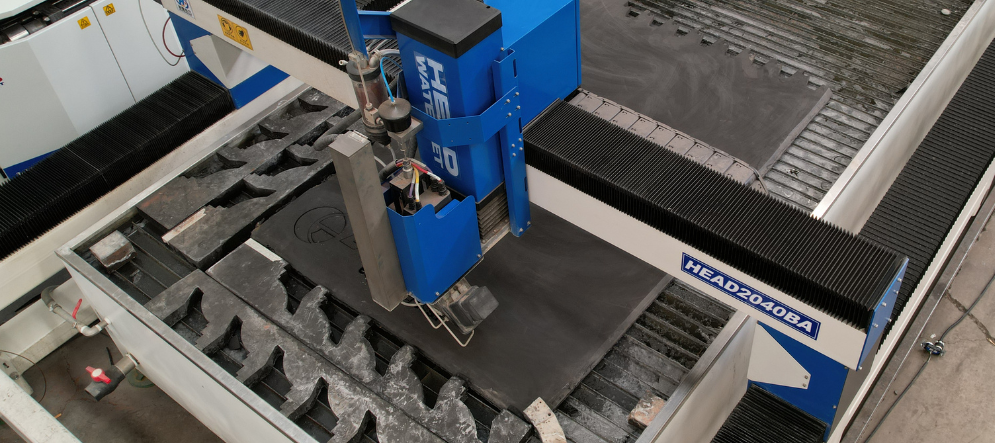

- Evaluate cutting efficiency: If you use automated machines for cutting Crosslink foam, calculate the cutting efficiency by comparing the amount of material lost during the process to the amount effectively used. You can refer to our article "How to Cut Crosslink Foam" for more information on this point.

2. Choose the right size for optimal yield

At Evacolors, we offer a variety of sizes to meet your material requirements. Take a look at our products list to evaluate which option provides the best yield, reducing expenses by acquiring a material that precisely matches your needs.

3. Test different products with samples

To select the sheet with the best characteristics for your needs and avoid choosing the wrong product that may increase production costs, we provide the option to request samples for evaluating the material's properties. Contact us to learn more about this process.

With over two decades of experience as Crosslink foam manufacturers, we can provide you with the material that suits your industry's needs, with shipping available throughout Mexico, the United States, and Latin America. Contact us or request a quote for your desired product.